|

The 65th European Study Group with Industry 2008

Problems

|

|

|

|

Warehouse

storing and collecting of parts

(problem

proposed by GROHE)

|

|

|

The

purpose of this problem is to optimize the time taken by fork-lifts

to collect and store parts in a warehouse.

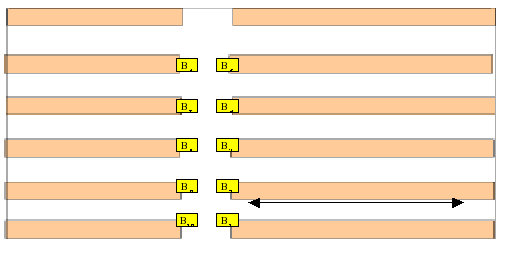

The layout of the warehouse is shown in the figure. There

are three fork-lifts collecting parts from the shelves and taking

them to a fixed base point, per each corridor, denoted by Bi.

At the same time, they take parts from B and store them in the

shelves. At each point in time, a given fork-lift may carry only one

type of parts which is to be either stored or collected. The storage

place of a given part is predetermined. Denoting

the parts to be collected and stored by C1,...,Cm and

S1,...,Sm,

respectively, we want to produce a list with the optimal pairing of

Ci's

to Sj's

(leaving |m-n| items unpaired if necessary) which minimizes the total

storage-collection time. Possible

further questions include the optimization of the layout of the

shelves, and also of the organization of the storage of parts

depending on past history.

|

|

|

|

|

Electrostatic

separation of rubber and textiles

(problem proposed by Biosafe)

|

|

In

the process of recycling rubber from tires, the end product should be

as clear of foreign particles as possible. Of all the tire

components, textiles prove to be the hardest to remove by the methods

already being employed by Biosafe (vibration, magnetostatic, etc).

Although for the larger grains the present process is satisfactory,

for smaller particles (typically under 2mm) it is difficult to

separate the textiles from the rubber. Because of this, the company

is thinking of using electrostatic plates as a mean to eliminate the

textiles in the final stage. However, existing methods of this type

do not necessarily extend to the materials being used, and they would

want to know if the method would prove to be feasible, efficient and

safe.

|

|

Cooling

of a rotor

(problem proposed by Biosafe)

|

|

A

steel rotor which is used to shred tires for recycling functions at

450 r.p.m. and has an allowable working temperature range. It is not

known what the optimal temperature is, but it should not exceed 80oC.

Very low temperatures, on the other hand, are not efficient –

typically, the first half hour has a lower output than the stationary

regime. In

the present configurations, the temperature can easily become higher

than what is acceptable (at least 100oC-150oC),

and the company is considering the possibility of cooling the system

by circulating a liquid (possibly water) inside the rotor. The

company would like to know how the cooling should be made, and if it

will be safe and efficient to have the cooling liquid inside the

drum.

|

|

|

|

|

Optimization

of task assignment in a factory

(problem proposed by For Ever)

|

|

In

order to carry out their orders of shoe soles, this company has a

number of tasks T1,...,Tn

of different lengths to be assigned to groups of machines. Each group

is operated by one worker (two in one case), and an operation cycle

corresponds to injection, cooling, and removal of the sole. The time

taken at each step varies from one order to another, and when

starting a new order a machine needs to be tuned, which takes some

extra time. Machines are working in parallel. At the moment the

assignment is carried out empirically, and the problem proposed is to

optimize the procedure.

|

|

|